Water. With all the advances in technology, it can still be the best product to clean hard-surface commercial floors. It sounds simple – and it can be – if it’s used with the right equipment and technique.

Are you a facilities or maintenance manager struggling to clean your hard surface floors?

Mannington responds to inquiries from facility and maintenance managers who are struggling to keep the flooring clean, even areas of the floor that don’t get a lot of foot traffic such as corners and along the edge of a wall. Let’s examine some of the issues and the way to address them to achieve optimum performance and extend the overall life of the floor.

In this article we are going to look at two flooring types, Luxury Vinyl Tile (LVT) and Sheet Vinyl. We'll discuss knowing your floor, specifically what kind of floor finish are you working with, Microfiber pads vs. traditional mops, and why you should be using 21st-century cleaning equipment on your commercial floors.

Color Anchor Sheet: Arc - Pavo, Prism - Snowpea, BioSpec MD - Bright White, New Glacier, Talpa

Get To Know Your Floor

First, know your floor. Does it have a floor finish? Is it factory coated? The process used to maintain factory-applied coated floors can be used on floors that have floor finish, but not necessarily the other way round.

Sheet vinyl and luxury vinyl tile (LVT) do not need floor finish; therefore, we see a reduction of chemistry, water, and man-hours in maintaining these floors. In fact, we’ve found we can successfully reduce chemical and water use by 40 percent when the right products and processes are implemented.

Now that we know water is the key component, what type of equipment is needed? The first thing that comes to mind is a mop, which isn’t wrong. The string mop was patented in 1890's and has served well, but for commercial cleaning, it’s antiquated.

Related: How to Clean and Maintain Commercial Hard-Surface Flooring

Microfiber vs. Mops

When cleaning luxury vinyl tile and sheet vinyl you'll want to examine your toolkit. Microfiber is a newer technology. A microfiber mop does not actually absorb liquids, it simply holds them. Even when flat mops are used according to the manufacturer’s instructions, they hold so many chemicals and water that the floor becomes over saturated.

When the water evaporates, the chemistries are left behind creating a residue that can actually attract more soil, so the process becomes circular and dirty water gets pushed around, often into areas that don’t even get foot traffic.

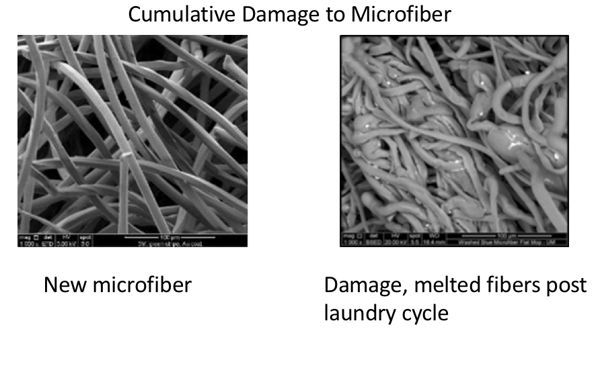

One of the issues we often see is a discrepancy in how to care for that laundered microfiber pad. A microfiber flat mop has a life expectancy of 300-500 laundry cycles. We have seen facilities keep their launderable flat mops far beyond their life expectancy, sometimes into the 1000 laundry cycles.

Depending on soil, a microfiber pad can load quickly and when it’s full, it has to be thoroughly rinsed or removed and laundered only with other microfiber products. The Centers for Disease Control and Prevention (CDC) recommends laundering at 160 degrees but some of the manufacturers say not to launder above 120 degrees.

Taking Care of Your Cleaning Equipment

When it’s laundered beyond its heat range capacity, the microfiber strands that are used to pick up and lift soil are denigrated and they can no longer perform as designed, even to the point of not releasing the soil from the pad when rinsed or washed.

We’re dealing with 21st-century flooring products; we should be using 21st-century cleaning equipment. We have seen a transition in the hand wiping industry where it started with a bucket and a cotton rag, evolving to utilizing microfiber, and now the use of disposable wipes is common practice both in home and in commercial use. The next logical step in the progression of floor cleaning supplies is laundry free single-use microfiber pads such as Premira® by Contec.

We’re dealing with 21st-century flooring products; we should be using 21st-century cleaning equipment. We have seen a transition in the hand wiping industry where it started with a bucket and a cotton rag, evolving to utilizing microfiber, and now the use of disposable wipes is common practice both in home and in commercial use. The next logical step in the progression of floor cleaning supplies is laundry free single-use microfiber pads such as Premira® by Contec.

Related: Commercial vs. Residential Floor Cleaning

Disposables? Won’t that be expensive? Let’s look at the bigger picture. When comparing a laundered microfiber to a laundry-free pad, Contec found there was a 44 percent reduction in disinfectant and cleaning solution. That’s a major reduction in an expensive product. And, since at least 80 percent of facilities pay for water, also helping them reduce water consumption can be another significant budget savings.

Cleaning Your Commercial Floors

The bottom line is clear. Using the same old chemicals, equipment and techniques aren’t an effective cleaning solution on newer hard surface floors like LVT or resilient sheet vinyl.

Mannington Commercial offers Quantum Guard Elite and Quantum Guard HP, on our hard surface flooring products, a proprietary technology that is naturally stain resistant and requires no-polish maintenance that significantly reduces overall life cycle cost and total cost of ownership.

If you’re a facilities manager struggling to see results after cleaning your floor with old techniques, consider switching to the right microfiber pad, water and a bit of agitation to solve the problem with even heavily soiled flooring products.

Additional information about accessories and equipment as well as maintenance instructions, is online at Mannington Commercial Technical Service or call 800.241.2262. to speak with a Mannington professional.

Use this guide to help you plan all your commercial flooring cleaning and maintenance.

.jpg?width=1080&name=ColorAnchorSheetPedHosp%20(2).jpg)