Most people associated with the flooring industry are familiar with traditional design and production of luxury vinyl tile (LVT). It’s a trusted process. But, there’s a fairly new game in town that’s changing the playing field. When compared with traditional LVT design, digital printing opens up opportunities with inventory, lead times, speed to market and design with longer pattern repeats, more dynamic color options, and more robust customization options.

Mannington Commercial already offers 112 LVT SKUs to market each year. The option for digital printing complements that product offering with even more design options. Investing in digital print technology for the Madison, Ga. production facility broadens the opportunities to design and produce even more dynamic product collections.

Whitney LeGate, Vice President of Commercial LVT and Joseph Delarso, Color Development Manager, talked with us about the technology and what it means for Mannington customers.

Mary Catherine Lowery:

If you could give our readers a general introduction to digital print - how would you explain it to someone who had never seen or heard of it before?

Whitney LeGate:

Digital print is surprisingly simple from a technical standpoint. Think about your office printer, except this printer is 12 feet wide. This larger version obviously has some nuances to be able to print on these scales, but it prints essentially like your printer at home.

Joseph Delarso:

Basically, we have the ability to take something – any scan, picture, image – that is digitized on a computer and reproduce that in print form. And we could turn that into Luxury Vinyl Tile flooring.

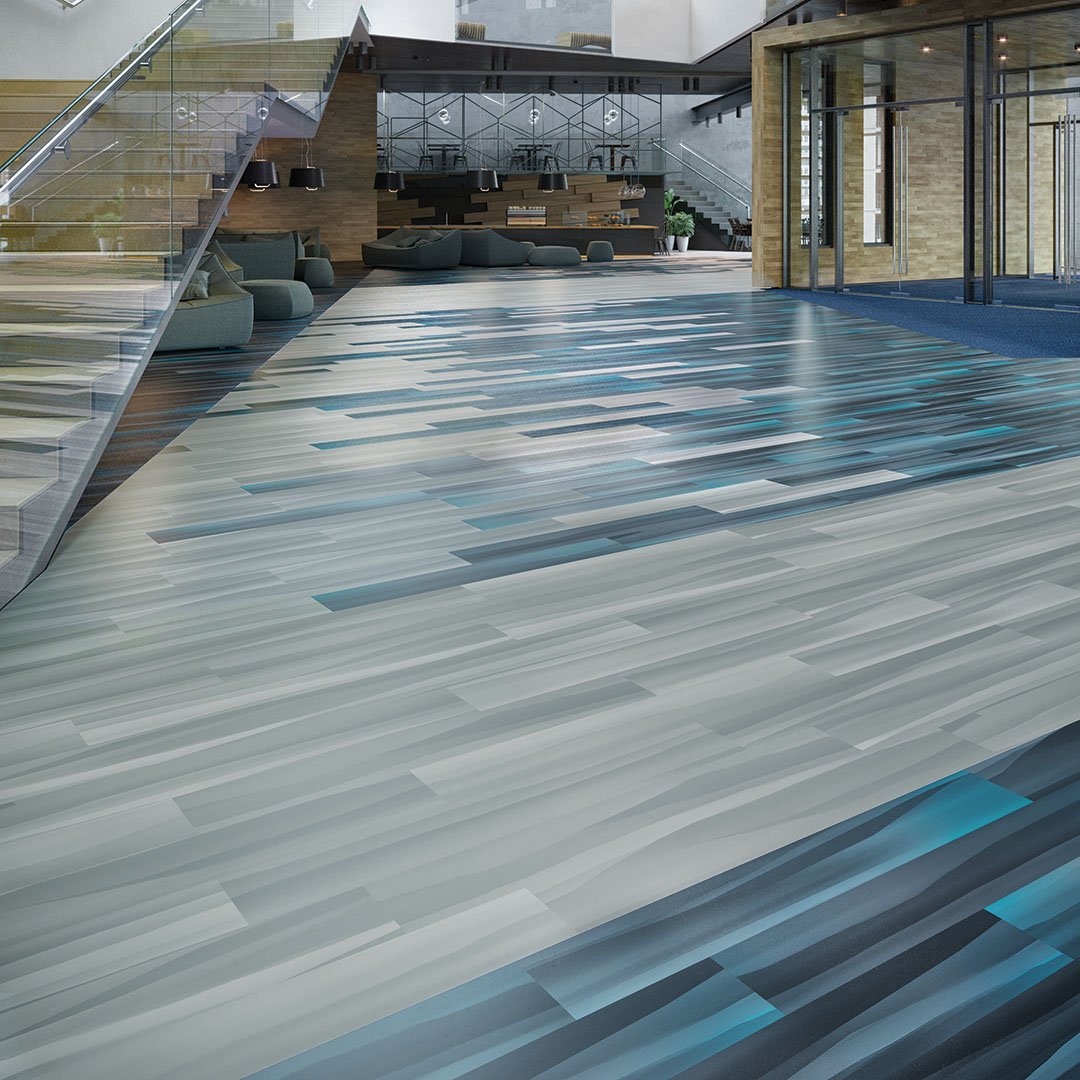

Amtico Northern Wonder- Aura, Mist

MCL:

From this 12 foot printer, the image is printed onto a film. Is this the same film used with traditional rotogravure?

JD:

Same exact film, and then you go through the same manufacturing process. An interesting part about our digital print LVT compared to some of our competitors is that we evaluated the machines and the technology in order to fit the process we had. We didn't have to add any new steps. A lot of the digital printers out there require some extra coding or something to make it work in a production line. We found machines with the right combination, the right profiling and the right color management for good quality that performs in our existing lines, giving us maximum development opportunities.

MCL:

Digital print allows for longer pattern repeats and more color values within the design. Are there any other specific ways you see digital print affecting design? How else is digital print different than the traditional LVT process?

JD:

Well, we can design with a wider palette because you don't have to limit yourself to the finite color stations that you have in the traditional process. So if a customer wants a color in a specific area that is totally different than the rest of the product, we can place that color separately.

With digital technology, everything is placed at the same time, so there aren’t any registration issues from color to color like you can have in traditional rotogravure prints. If you're only running four colors on a rotogravure press, each cylinder has to be engraved which is a substantial amount of money, so you're limited by that color gamut. If you're picking four different grays, then the pattern is going to be gray. Digital print allows you to have parts of the pattern that feel very neutral, and also transition to colors that are very saturated, all on the same print.

MCL:

Are there any color limitations to digital print?

JD:

There are some. The technology is still so new, and a lot of the chemistry for the specific vinyls that we work with are still developing. The limitations come down to the type of pigments and the carriers that actually get the pigment through the machine and onto the film that we use. There are limitations with some of the different pigments, but we understand those tones and saturations so we can guide color selection based on a library related to Pantone®.

WL:

To add to JD’s comments, the performance limitation with prints can be lamination. When you have too much color saturation on a print, products won’t laminate correctly. That’s something we closely monitored in development of digital prints considering performance is a key element of our product across all of our LVT lines. You can have that same issue in rotogravure prints as well, so it is something we are always mindful of in all our design development. This whole process of digital print development has been a lot of learning for us in regards to how inks react in different environments including heat, pressure, etc. It has been a great project for our teams.

We recently launched a LVT Wayfinding collection, which is really more like a personalized digital tile collection. As part of that, we put together a Pantone color book so our customers could easily navigate through which colors we know can be produced at our required quality level. All the color values and details on how the collection works is available on our website, but we wanted to make it something easy to design and install. For example, in our Wayfinding LVT, we sell it by the piece so there's no minimum. We can print them on demand, leveraging our domestic production. Being a domestic supplier, we are able to really leverage the capabilities of luxury vinyl tile digital print and bring that flexibility and design element to our customers.

Related: What Is Wayfinding?

MCL:

As far as inventory and lead time, what does digital print bring to the table?

WL:

We've found that digital print is a great way to let us leverage a more complex and diverse collection with bigger color palettes without having to put the burden of substantial inventory cost on top of that product. We're able to leverage that digital printing technology to help us bring down that inventory and our lead time. We're able to make it much faster, which allows us to better service our customers.

MCL:

Why do you see digital print becoming more popular?

WL:

Digital print is becoming more popular because it allows you to expand your design capabilities beyond what we current can do in traditional LVT print development. However, it's a unique technology that most people aren't able to fully utilize. One challenge is that digital can be less cost effective than some other methods of printing.

Most LVT print is sourced from outside suppliers, whether that's in the U.S. or Asia, so it can be a challenge in terms of supply chain. But logistically, making a digital print ourselves gives us a lot more control, and we're always pushing to control our own destiny, which is one of our core values. We feel it’s a great fit for us with more than 90% of our commercial LVT made in the U.S. in our Madison, Georgia facility. We are excited to bring more design options to our customers through our digital print technology.

Yet, there's still so much you can do; it's still certainly the go-to print methodology. I always tell people, print is more of an art than a science; the way the colors change and how the prints and inks react. There’s so much technology behind all of that, but there's a lot of art behind it too.

Related: 6 Reasons Why LVT is Growing in Popularity

Northern Wonder- Aura, Nightfall

Digital print lets us explore some of those areas that we can't in traditional printing, which is what we did with our first digital print LVT collection, Northern Wonder. We pushed the boundaries of creating something that would be exceptionally difficult to do in traditional rotogravure print. Very long repeats. Really stretched out color. A beautiful LVT product, unlike anything we've seen in the market. We continue to see a lot of opportunities to leverage digital print in our domestic flooring manufacturing.

The flexibility and customization options are valuable and give us an advantage. We're using our digital print technology in our domestic manufacturing to bring in accent colors. Since we have a whole customization option, a client can choose whatever Pantone color they want for a pretty low minimum.

We provide a quote like designer notes on how to best choose custom coloration. We also can take a base print and print on top of that. We just made a digital print that's a green teal color so a hospital can put it in a custom cut. That’s just one example of the possibilities with digital printing.

The full impact of digital printing is still being realized as the design and production teams continue to learn new ways to capitalize on the technology. We know it delivers color options and flexibility for customers and manufacturing benefits. So, it’s a winner all around. To learn more, contact a Mannington Commercial representative.

Would you like to keep learning about Luxury Vinyl Tile?

In this guide, we’ll cover the basics of LVT, Rigid Core LVT, how to choose the right LVT and help you ask and answer the right questions to specify LVT for your specific commercial end use.