What do you picture when you think of vinyl flooring? You probably picture a residential kitchen floor from the 1970s in what we would consider less-than-groovy colors these days.

Looking at the vast variety of commercial sheet vinyl offerings today, we can see how far the designs have come since emerging in the marketplace.

In this article you’ll get a behind the scenes look at:

- How sheet vinyl got its start

- Conceptualization and pattern development

- Manufacturing and the Rotogravure Process

We sat down with John Traini, Senior Designer at Mannington Commercial, to share with us his knowledge of how sheet vinyl is designed and manufactured. John joined the Mannington team over 28 years ago while he was in college studying Illustration and Graphic Design at Rowan University.

During his college days, he worked in the sample department, but it wasn’t long before he landed a job in the design studio, working first for residential before making the switch to commercial. John’s many years of experience made him the perfect person to give us a behind the scenes look at how exactly sheet vinyl progresses from design concept to installation.

How Sheet Vinyl Flooring Got Its Start

'Vinyl' or 'sheet vinyl' is part of the resilient flooring family that has been around for decades and is still one of the most popular types of flooring around. It's made using a printing process known as 'rotogravure,' which prints a pattern on the flooring substrate via a series of engraved cylinders. It’s typically produced in twelve -, nine- and six-foot widths.

Since introducing commercial sheet to the market in the late 1970s, Mannington has made many advancements in the product to make it even more robust for those commercial applications.

The product needed to have superior indent resistance under heavy load, could not scratch in high traffic areas, could not easily puncture / gouge, and needed to be dimensionally stable to prevent seam opening problems.

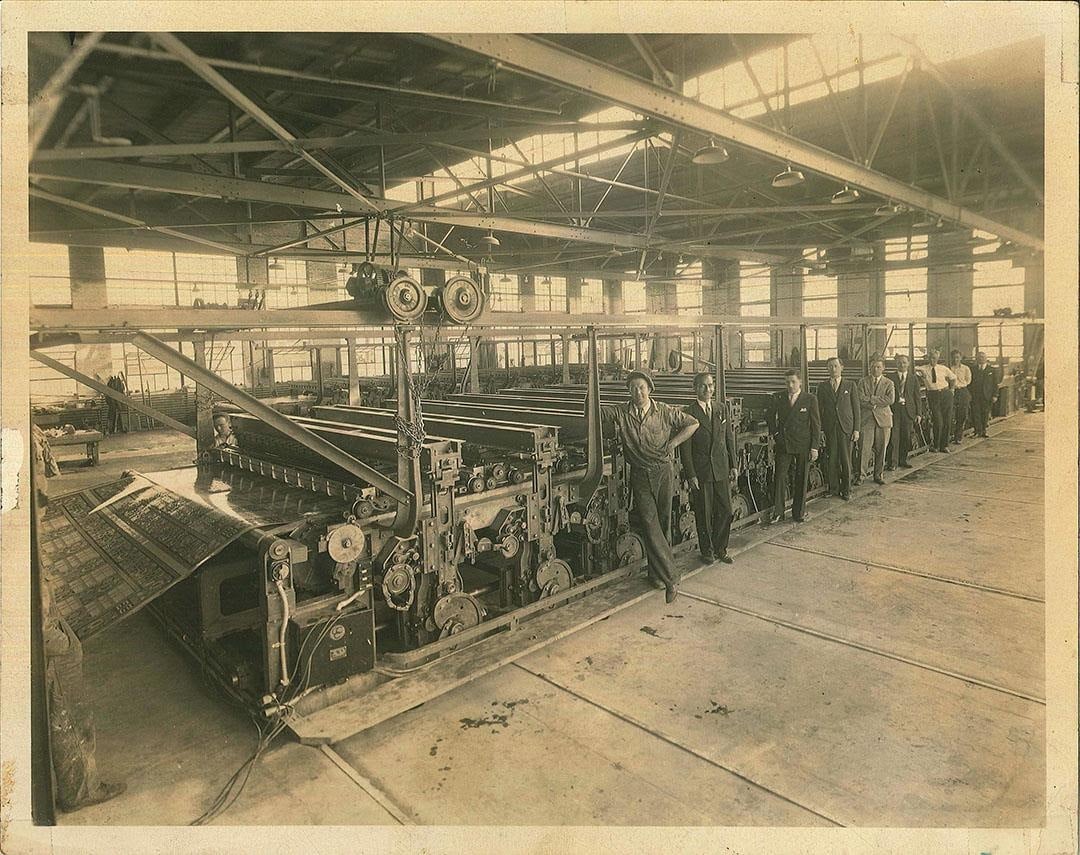

Mannington in Salem, New Jersey. John Boston Campbell and sons operating a little vinyl floor covering company

Over the years, with lots of experience and trial and error, we have learned how to combat these issues and adapt our manufacturing processes to provide a product that can handle all of the issues facing commercial flooring.

Conceptualizing & Pattern Development

At Mannington, pattern development starts with exploration. Our designers are asked to use experiences to build creative concepts. The creative research they do is also combined with research from the market. We seek to understand what patterns and colors are trending, but also how the space needs to function.

We often ask ourselves how our new flooring design can aid in the overall design of the space, knowing it is just a piece of the puzzle.

For example, incorporating biophilic design principles into the architecture and interior design can help aid the healing process for patients who are exposed to this type of environment.

The commercial design team reviews trends in various sectors such as healthcare, education, retail, etc. The goal is to stay ahead of the curve with looks that are in tune with what both interior designers and end-users want to see while ensuring the product quality stays unparalleled through the manufacturing process.

After extensive research both in the field and through creative exploration, John will develop pattern concepts for internal review. John’s first series of pattern work will have varying scales, play with different geometries, and explore color in a variety of ways. This is the part where all the conceptualizing and research come together and are expressed in visual form.

Bloom Collection: Meander, Renewal

Bloom Collection: Meander, Renewal

After many in house design reviews and iterations to the patterns, we will narrow down the pattern selections and take them out to the field for feedback. These concepts are then presented to designers, located all across the country, for feedback on color, pattern and construction. It is an integral step to ensure that the voice of the customer is heard.

Each new pattern John develops is made to align with the repeat parameters of rotogravure printing, which are set by the cylinders which are 36” in circumference and up to 12’ wide. This repeat size is very important because it will become evident at install if there are seaming issues, tracking within the pattern, or other visual faults within the design.

In this way, sheet vinyl is very similar to wallpaper — it needs to have a pattern match at all sides, and you want the pattern repeat to flow and not have one motif stand out too much.

Once the targeted patterns for the collection are decided, representatives from design, manufacturing and quality meet to review the designs to evaluate any concerns so appropriate adjustments can be made before proceeding. This holistic team review attempts to address issues before they arise further in the manufacturing process, or worse, after a product is installed.

Manufacturing and the Rotogravure Process

When a final design is approved and the colorways are finalized, the next step is to prepare for printing. For our heterogenous sheet products we use a rotogravure printing process.

What Is Rotogravure?

Rotogravure (or gravure for short) is a type of relief printing process that involves engraving an image onto an image carrier. In this case, the image carrier is a cylinder made up of a steel base that is covered with copper and, after being electro-mechanically engraved, gets covered in chrome.

The copper surface helps with the functionality of printing allowing for engraving, stability in the press and reproducibility. Chrome is added to the copper layer because the copper alone would not be able to withstand the friction of the doctor blade long-term.

Unprotected copper would wear out over time, which would in turn wear down the patterns that were engraved.

Once the cylinders are engraved they will be placed into a print station on the printing press. There could be anywhere from 2 to 6 cylinders used to create just one pattern. At each print station there is an ink tray with its dedicated ink color, the engraved cylinder, a doctor blade, and an impression roller. As the substrate moves through the press, it will come in contact with each cylinder at every print station.

The cylinder rolls through the inkwell, which gets skimmed off by the doctor blade, allowing the hallowed engraved areas to capture the ink. The cylinder with ink then comes in contact with the substrate it is printing on. This substrate is being pressed into the cylinder by the impression roller. This helps to make sure the ink is evenly distributed across the substrate, replicating the pattern perfectly each time. This is called the KISS method.

The engravings on the cylinder are called cells and are carved into the cylinder in a diamond shape. Each cell or diamond shape can be large or small and can be very deep or very shallow, depending on how strong you want your colors to read for the pattern. The larger the engraving and the deeper the engraving, the more ink the cylinder will pick up, the darker the ink color reads on the substrate.

Keep in mind the ink is not entirely opaque. By having a somewhat translucent ink, it allows the color to be layered from station to station, layering in the patterns engravings from each cylinder giving the final product more visual texture and depth.

Once the substrate has moved through all of the print stations and all the colors are applied, a wear layer will be applied to the roll. The material passes through a very hot oven and the final fusion of all the layers takes place. This process gives the product its surface properties for superior install and wear performance in demanding environments. It is then prepared for cutting, shipping and installation.

The Final Flooring Product

What seems like a lot of steps depends on key expertise from those in design, research, sales, manufacturing, quality control along with trusted vendors.

Each plays a key role in ensuring the design will satisfy the needs of the end consumer, both in terms of the look and the durability of the final resilient flooring product. Every pattern is thoughtfully curated and expertly created to meet the Mannington standards of excellence.

If you design a lot of healthcare spaces and use resilient sheet vinyl flooring we made this top 10 list for you.