A Roundtable Q&A

When specifying LVT, it’s important to consider all the various elements of the flooring, design and installation to help your project meet your vision and expectations.

In this article we gathered four key people for a round table discussion — Whitney LeGate, Director of Commercial LVT, Roby Isaac, VP of Commercial Design, and Dennis Koutavas and Anthony Faulknor from Mannington’s technical services team — to take a look at one of the new spec guides for specifying Amtico Signature Luxury Vinyl Tile (LVT).

After an LVT product is chosen for the project, there are still several decisions to be made regarding LVT before an order can be placed.

This guide will look at how each element of that decision process will affect the performance, design and maintenance over the lifetime of the product.

When selecting an LVT flooring for a project, consider these six steps to guide you to the right choice, considering both the visual and the performance features. It's not quite as simple as walking into a store, seeing a shirt and saying, "Okay, I need this in a size medium." Once you've picked the design that you like and you have an idea of the visual, there are other choices to make that will have a huge impact on the final look and overall performance of your floor.

The 6 Steps to Specifying LVT:

- Choose Your Visual

- Choose Your Size

- Choose Your Edge

- Choose Your Emboss

- Choose Your Pattern

- Complete Your Order

Our group of panelists will explore the 6 steps above and explain how each is a key factor when it comes to specifying LVT.

The Drift: Stone, Terra Diamond

Q: How do you choose the right LVT flooring?

Whitney: Aesthetics play an important role, but when you're thinking about your commercial space, you want to think about what you want the product to be able to do in terms of performance for the life of the floor.

Not every installation needs to be down for 25 years, some are short-term or more medium-term projects. You also want to think about the amount of traffic that you have in the space. All of that's going to lead to your performance characteristics, which are typically specified in the wear layer.

Q: How does plank and tile size affect flooring design?

The first step in the process is choosing from an incredible range of visuals and performance features, once you get past that first step, you know what you want, and now we're in the ordering process. Next is choosing a size, and there are a ton of size options across the flooring industry and within Mannington’s LVT line.

Roby: The visual piece really is dependent on what you want that space to convey. Once you determine what that is and then marry up the LVT visual to that feeling, then sizing becomes the next piece. When we work on projects or when we've talked to designers who have worked on projects, a lot of that is dependent on the size of the space.

So you wouldn't necessarily want to do these really large pieces or planks or tile widths in a really tiny space. It just seems a little bit incongruent with what that space is trying to do, and it just might feel too heavy in that space. So oftentimes, we find that projects use larger tile planks and tile sizes in large, more open, expansive types of spaces.

Choosing A Flooring Tile vs. Plank Flooring

Roby: When you're thinking about tiles versus planks, planks help elongate that space to try to open it up a little bit more. So if you have a corridor that allows for planks to support it, we often see planks going in there.

But we try to also provide different sizes within all of the plank and tile range, anywhere from a 3" x 36" to a 7.25" x 48" in the planks. And then we've done collections where we have smaller, 9" x 9" tiles all the way up to our largest which is our 18" x 48" tile to again, really pronounce the space by the tile that can be used in it.”

Whitney: From someone who doesn't install LVT every day, I've been surprised how different sizing makes the product look. So it's so important to understand that for your space, and we have a great tool online that shows all of our products in the various sizes that they come in.

We recently launched a collection called Drift that has the Pax pattern that comes in a tile and a plank and looks completely different depending on the size, but I think both are beautiful in their own way. But such a great tool to have a visualizer to let designers see that ahead of an install.

You Might Like: The Specifiers Ultimate Guide to Luxury Vinyl Tile (LVT)

Does plank and tile size affect flooring installation?

Dennis: It's going to affect the cut sizes, and it's going to affect how the installer goes about pre-planning for the project. That's where the designer comes into play with the installation team as to what the expectations are and a lot of times, there might be a project where there's a certain inset that has been planned to be installed.

Let's say at an intersection of a corridor. And the size format matters a lot if that inset cuts into the size of the planks or the tiles because of having to make the inset, put the inset in place and then install around it. The installer is responsible for giving the optimal size cuts throughout the space as much as possible.

Whitney: There are benefits and potential challenges, depending on the size that you pick, but the smaller you go, the more easily it is to manipulate that tile on a floor and fit it together, right?

Dennis: That is an excellent point. Usually the smaller the tile, you can end up with a lot less waste. And you do have more options as far as layout is concerned. The bigger the format, the less, the fewer options you have to work with, put it that way.

Let's say you're doing a larger room. A larger tile would help you lay that room a bit quicker. Smaller tiles, smaller planks are very labor-intensive because you're covering less area with each movement.

So medium to large size tiles, you can cover a large area. But once you get into corridors and you get into a lot of doorways and some intricate cuts, the larger tile or the larger modular segments, they pose a bigger threat because one mis-cut, you're throwing away a lot more square footage, or you're challenged to reuse it an area where you can use it as a cut somewhere else. Especially if you're working on a diagonal or something like that.

So the larger the tile, the greater the challenge for the smaller areas.

Q: Advantages of a Bevel or Square Edge for LVT?

Once we've established the product and chosen our size, the next option is choosing the edge. For Mannington, you can choose from unbeveled (square edge) or beveled edge options. Our team explains why that choice is an important one not to gloss over and how it affects the overall look and installation of the project.

Whitney: Our default is typically a bevel edge. We do have a few collections that come standard square edge but most of our collections you can get either way. Specifically our Amtico Signature Collection offers all sizes and colors in both edge options running line.

Our new Drift Collection, because it is healthcare focused, it's available with both edge profiles as standard. But because we make 95% of our commercial LVT in the US, we have the flexibility to offer almost all our products both ways.

So why one over the other? Typically, a bevel, which is just a machine that shaves off the edge to give you a slight bevel, almost a little V when you put two planks together. It's actually more of a V with a flat bottom is how it meets together.

It tends to have a more realistic look, specifically in planks, it can also "hide some sins" of the subfloor. If you have any subfloor irregularities, one edge may come up just slightly more than the other, and over time that may cause a lip in the product where dirt and grime can build up. A bevel can help hide this whereas a square edge product may not.

Different market segments will prefer different things. We have seen in recent years the healthcare market really drive towards a square edge. The consensus is that it's easier to clean, less buildup in the seams. Again, it depends on your installation.

It could be argued either way, but for those who do want square edge, we have that option. So it's an easy choice, but you do want to make sure you specify it. That is something that's a little bit unusual to be able to have both. Most suppliers only have it in one version, particularly if it's sourced.

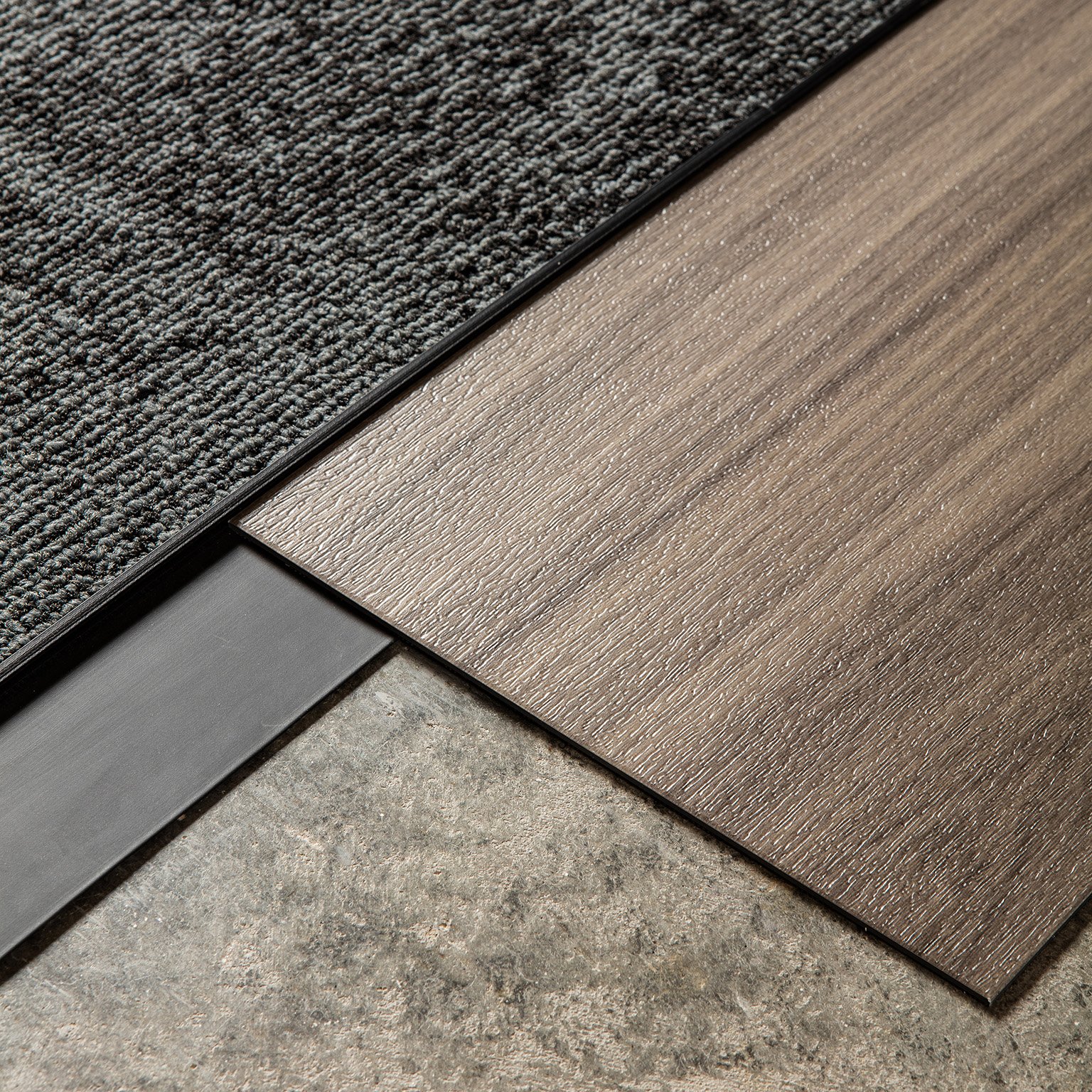

Example of a Microbevel & Fusion Transition Strip

Does LVT Edge Profile Change The Look Of The Floor?

Roby: We offer a lot of the beveled edge options, and I believe that part of the reason they're more used is because it contributes this realism that we're all trying to look for when we place product on the floor, that ties back into what typical or traditional wood planks would do when they're laid down. There's that little bit of hint of recess and when planks are laid down, you get that almost natural quality to it.

Depending on the type of bevel you have, you can feel like it has that feel of real wood. The straight edge, I believe, offers more of a minimalist, clean look where you want the floor to seem monolithic or seamless when you put all those planks and tiles together.

Are there Installation Differences for Square Edge vs Beveled Edge LVT?

Anthony: One thing about square edge and beveled edge, if you're doing an inset, something you need to cut in a different color or a design, and you're trying to do it on site, the proper product would be a square edge because once you make a cut and it's straight from one curve to the other, if you had a beveled edge, there's no way to get that bevel back once you cut it. So the square edge is better when you're doing intricate cuts and things of different colors on-site.

Q: Does Emboss Affect LVT Flooring Installations?

We have covered edge, size, and choosing the product. The next step, logically, is choosing your emboss. Unlike many sourced LVT products, Mannington offers the ability to personalize which emboss will best fit the needs of your space on our Amtico Signature Collection.

Whitney: It starts at the design level. You want a realistic visual. Something that feels like the product would really feel. We put a lot of thought into that when selecting the standard emboss on a product, and we also put thought into how the emboss performs in the space.

You won't typically put a heavy barn wood texture on healthcare-specified products because in that environment, it can be slightly more difficult to clean, or potentially trap more dirt. Healthcare tends to gravitate towards a less textured emboss specifically for those reasons.

We put a lot of thought into the target market segment, the realism of the product, and then just general market trends. Commercial design tends to take some cues from the residential market and we've seen that market move away from heavy knotholes or that real heavy rustic look to smoother, what I'd call elevated woods that have more of an artistic quality.

A specifier should be really thoughtful about if you have this beautiful, soft print or subtle design and then putting a very strong or mismatched emboss on it, it could really ruin the look of the product.

Emboss can also change the gloss effect to the product. The shininess or the appearance of shine. Changing that emboss is a factor in that aesthetic, so we take that into consideration as well.

On our Amtico Signature Wood product line, we offer both a tick and a barn wood finish so that the end user can choose, because it's such a large line and it does go into so many different market segments. We didn't want to make that choice for the customer, we wanted to open it up to them.

We also added in a few new embosses this year. Rustic is a new emboss in Amtico Signature that is a mix between that tick and a heavy barn wood, as well as some new smoother ones as well.

How Do You Choose The Right Emboss For Commercial LVT?

Roby: When we're looking at the options for an emboss, the available options aren't always as limitless as let's say, the print film. Sometimes we have to look at a catalog of options, and we try to marry up the best graining emboss with the visual that we're printing and turning into LVT.

We want to make sure that the character of the two work well with each other so that, as an example, you wouldn't want to take something that's maybe more heavily rustic, like a barn wood, and then do something that's really smooth on top of it, like a fine tick wood grain. Or vice versa, where you have something that's really clean and simple and soft, and put something that has this heavy, rustic grain on it.

It just feels wrong when you're looking at it, when we're developing products and looking at it, holding it in our hands. But when you put it on the floor, it just would appear less authentic than what we're really trying to convey. We take a lot of time looking through these catalogs and the options that we have, and then pairing them to get that right fit.

We do that not only for woods, but we do it for the abstracts and the stones, where stones you might want to get a tumbled type of look that mimics what natural stone might feel like over centuries or decades of weathering. In a positive way, of course.

With the abstracts, you wouldn't want to put something that was so disparate like wood grain on top of an abstract. We would try to do something that might be a little bit more simplistic, maybe just a fine little texture.

What it comes down to is making sure that once it's all put together, the emboss, the wear layer, the print film, and the backing, that all of it feels right. We're trying to make a product that is durable and aesthetically pleasing. That it performs well but looks good at the same time. So all of those things need to marry up, and that wear layer piece is extremely critical.

Does Emboss Affect The Maintenance Of The Flooring Product?

Crafting the perfect level of emboss is an industry-wide challenge. A balancing act of what is too strong of an emboss to be cleaned and what is not quite enough to look real. In the product development process of a new emboss there is substantial testing to make sure that it's maintainable.

Dennis: I've seen it where the ticking just holds on to a certain amount of dirt that if you don't get that consistent cleaning or that little bit of extra or special type of a disk on your cleaning buffer, it may not clean out too well.

With a very heavy emboss, over time, you start seeing patterns, and it just takes a little bit more effort to clean out. So the deeper the ticking, I think the more that the soil gets trapped. It's harder to remove. And we have seen some of those challenges, and I think we've really overcome them well over the last few years.

Anthony: At Mannington, we do substantial testing before the products are ever launched, we install it in an area of one of our facilities to measure foot traffic. We’ll add extra dirt and different things intentionally. Then we try to clean it through a standard recommended cleaning process to evaluate how difficult or easy it is to clean for our customers. They're going to be going through the same thing. So we try to test that and make sure that the floor can be easily cleaned with a routine mopping process.

We suggest a deep clean quarterly, but our priority is that our customer needs something that will clean with a mop and a chemical or water. It's a routine thing that we do with all of our products. Dennis is correct. The deeper the emboss, it becomes more difficult to clean.

There may be a trade-off between the authenticity of a wood look product with a very strong emboss versus the cleanability required in a healthcare environment, so you may go with something a little bit lighter to ensure that cleanability. Even though across the board we have done our best to make sure that all of those embosses are very cleanable and easy to maintain.

Q: How Do I Choose an LVT Laying Pattern?

Technically, any of our customers could stop there and that is the final step in the specifying process. Send it in, we'll get it shipped out to you, and you will have a beautiful floor.

But we also have an incredible range of options in the next step. The fifth step here is choosing a laying pattern.

Roby: If the visual options and the size options weren't enough, we know that there are a lot of spaces where you want to just input your own creative slant into this and make it more unique than some other projects that you might have worked on, or just give your own signature to the projects that you worked on.

So what we've been able to do is develop these suggestions or ideas where you can take a style or a certain number of styles and, in a pre-formatted way, lay them down in a combination to enhance the space.

So you may be able to accent a space with these laying patterns where most of the remaining space is something a little bit more simplistic, like just a traditional wood or a stone, and then you wanted to accent or highlight a space. And you take these laying patterns and it's your wow for that space.”

Pilgrim Oak, Laying Pattern: Woven

Q: What Flooring Accessories Do I Need To Complete The Install?

All of the information leading to this point is exactly the questions you'd have to think about to specify and/or order LVT. But we can’t forget about accessories. Sometimes it is the small finishing touches that really make a difference. For example, we can transition your Signature floor or any of our LVTs to carpet using a Fusion rubber transition strip that we have that's affordable, flexible and easy to install with.

Specifiers should also consider adhesives and moisture challenges, which we have great articles from our team on that as well.

Whitney: We know how hard specifiers work to make their project come to life.. There's nothing worse than checking all the boxes and then it not ending up the way that you want it to be. There are a lot of elements you have to think about in terms of finishing your project. So we try to cover the bases beyond product as well.

You have to think about things like moisture. We offer QuickStix, which is a pre-applied high-moisture adhesive that can be put on most of our domestic LVTs. It comes with our warranty. It matches the warranty of the product of up to 99% RH as long as there's an intact vapor barrier in the slab.

You've got that option, but maybe you didn't know about it ahead of time, so you'd like more of a traditional wet adhesive. We have multiple adhesive options for under-bed and healthcare, high-moisture slabs, etc.. We've tried to simplify the adhesive story. We have a guide that gives you recommended adhesives based on moisture conditions. We want to make it as easy as possible.

You also have to think about things like, do you need an underlayment? Are you trying to hit a specific acoustical or IC rating for multilevel buildings? We have a product called Silent Solutions that can be used under the majority of our LVTs to enhance that IIC rating.

We also make walk-off carpet. A critical piece to a project to maximize performance. It's one of the biggest things we see if there's not enough of an entryway.

Thinking about all those elements will help you finish a job and have it look and perform as you intended.

A Holistic Approach To Specifying LVT for Commercial Flooring

Roby: I'll just add one thing. I think in listening to Whitney and Dennis and Anthony at the end, the thing is that when you're looking at LVT, it's like with any other product. We should all be thinking about it holistically. It's not just, "Oh, that looks good. I want to use it and I'm going to put it on the floor and it's done."

There's so many considerations that go into it, starting off with what you want to say or what you want your space to speak to. But then how's it going to perform?

What else is going to enhance it or subdue it? What are the things that are going to increase the longevity or the lifespan of it? And how does that impact cost? So there's a holistic approach to the purchasing of this type of product.

Would you like to keep learning more about all things LVT?

Click below to download The Specifiers Ultimate Guide to Luxury Vinyl Tile (LVT).

.jpg?width=1108&name=AmticoSignatureWood_PilgrimOak_SignatureLayout_Woven_RS_Cafe%20(1).jpg)