How to prevent moisture issues and adhesive failures on concrete slabs.

Just like water and oil don’t mix, neither do water and flooring adhesives. New Yorker readers once voted “moist” as the word they’d most like to eliminate from the dictionary – but we must talk about the moisture in concrete slabs in order to avoid a flooring failure down the road.

Moisture claims are inevitable. Any flooring manufacturer will deal with them. We help our customers through their moisture issues as it relates to flooring and now hopefully this guide provides you with information that will help you avoid potential moisture pitfalls, we’re going to address the following questions about moisture and how it can cause a flooring failure:

- Why Does Moisture Matter?

- How to Prepare Concrete for Flooring

- How to Test for Moisture in Concrete

- What Could Go Wrong?

- How to Solve Moisture Issues in Concrete Floors

Why Does Moisture Matter?

We all know, excess moisture adversely affects flooring. Addressing the causes and the solutions is key to long-term quality.

Let’s start with some background.

Before 1979, with adequate technicians, adherence wasn’t a major issue for flooring material because petroleum based cutback adhesives were used to hold flooring in place.

This solvent‐based adhesive was durable as well as water‐resistant. There was little to no concern about adhesives being able to hold flooring in place and there wasn’t much concern about flooring “failures” post installation.

In 1991, due in part to indoor air quality issues related to carpet installed at the EPA headquarters in Washington. D.C., adhesive manufacturers began voluntarily producing low VOC (volatile organic compounds) formulations.

This decision was further solidified by the Clean Air Act Amendment of 1998 which required companies to register with the EPA if VOCs exceeded specified levels. So over time use of cut back adhesive has been significantly reduced.

As part of the reduction in the use of cut back adhesive and the introduction of lower VOC products, moisture failures began to increase. The new, indoor air quality friendly products could not hold up under high moisture environments.

We are now beginning to see technological advancements in the adhesive and floor backing industry that allow us to solve these moisture issues without creating adverse air quality issues.

Would you like to learn more about moisture while earning AIA/IDCEC CEU credits?

Click below to request the CEU, Moisture: Why It’s a Hot Topic & How to Mitigate It in Flooring Installations

How to Prepare High Moisture Concrete Slabs for the Flooring Installation

You’ve heard the old adage, measure twice and cut once? The same goes for the success of your flooring installation, when it comes to moisture, it is all about preparation.

Before any type of adhesive is applied, it’s imperative for the underlying surface to be properly prepared.

ASTM International (formerly the American Society for Testing and Materials) is the global leader in the development and delivery of voluntary consensus standards. One of the standards is F710, labeled the “Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring.”

This is the most common reference for flooring manufacturers, including Mannington, and includes installing a moisture barrier to inhibit the transmission of water vapor, cleaning and testing the slab, and ensuring the materials and environment are properly acclimated.

First, before we even think about testing the slab for moisture or prepping the area, for new construction, the contractor will choose an effective, permanent moisture vapor retarder, which is basically a flexible plastic sheet placed over soil or granular fill and under a new slab when it’s poured. ASTM 1745 is the standard.

There are three classes in the standard:

- Class A ‐ Maximum of 0.1 perms, minimum 45 lb/in tensile strength, 2200 grams puncture resistance

- Class B ‐ Maximum of 0.1 perms, minimum 30 lb/in tensile strength, 1700 grams puncture resistance

- Class C ‐ Maximum of 0.1 perms, minimum 13.6 lb/in tensile strength, 475 grams puncture resistance

The class in turn is based on permeance, tensile strength and puncture resistance:

- Permeance is the ability to resist the migration of moisture. It is measured in perms, which are defined as one grain of water vapor per hour, per square foot, per inch of mercury. The lower the perm rating, the more protection the product provides.

- Tensile strength is the pounds of force per inch that a retarder can withstand.

- Puncture resistance is the measure of how well the material can withstand the impact of a blunt object.

Most flooring manufacturers will suggest a Class B or better moisture vapor retarder for any new construction, but check their website or ask the manufacturers rep for any specific requirements.

For existing structures or after a new slab has been poured, the slab should be clean, free of any adhesive residue including cut back adhesive, dry, and structurally sound.

Then ensure the flooring sundries and environment are acclimated.

But, what do these terms really mean to an installer? And what actions are required? The key to knowing the best product to use is to test the moisture levels in the slab.

How to Test for Moisture in Concrete Slabs

Recognizing there could be a problem and understanding the implications of possible solutions requires thorough knowledge of all the factors involved. That means testing each element.

The moisture level in a slab is composed of three readings: relative humidity, moisture vapor emission rate and/or pH.

Relative Humidity

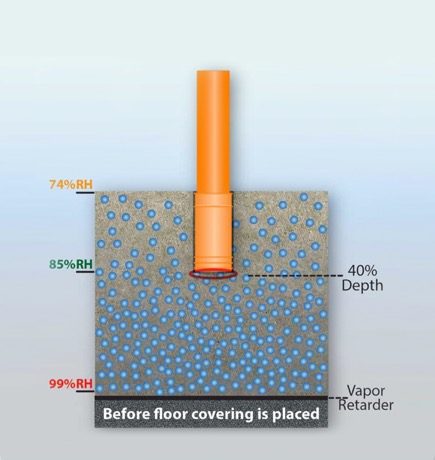

Relative humidity (RH) is the amount of water vapor present in a substrate compared to the amount of vapor present at total saturation. It’s the percentage of moisture within a slab relative to how much it could hold.

This is tested by drilling 40 percent of the way through a slab, if it is only drying on one side, such as a slab poured on a foundation. If both sides are able to dry, like a slab on an upper level of a building, it would be drilled 20 percent of the way through.

A relative humidity sensor is then placed into the hole and allowed to equilibrate for the manufacturer’s recommended time. The RH reading is shown on the probe.

Moisture Vapor Emission Rate

Moisture vapor emission rate (MVER) is also called a calcium chloride test and measures moisture on the surface of the slab.

It is performed by sealing a small dish of calcium chloride on a clean section of concrete under a plastic dome. Once sealed, it is left for three days to absorb the moisture released in that environment, presumably from the concrete.

The resulting dish is weighed to see the amount of moisture it absorbed or the difference in weight after the three days to find the rate of emission.

Potential Hydrogen

Potential hydrogen (pH) is a scale of 0 to 14, with below 7 considered acidic and above 7 as alkaline. Fresh concrete is usually 12-13. When moisture level is higher, the pH is higher but as a slab cures and moisture evaporates, the pH should move lower.

For existing structures or renovations, though, pH levels can vary widely so it is recommended to test for it when looking at which adhesives to use.

While pH meters are available, the more common testing method involves paper testing strips. Distilled water is placed on clean concrete and allowed to sit for 55-65 seconds. The pH paper is dipped into the puddle, removed immediately and the color compared to the testing chart.

What Could Go Wrong When Installing Flooring Over Concrete?

The idea of hoping for the best and preparing for the worst doesn’t fly when planning and installing flooring. Testing and thoroughly understanding how to deal with the results means making smarter decisions throughout the installation process. Let’s look at some potential scenarios.

If the slab has a high RH reading and the wrong adhesive is used, it will likely emulsify and ooze at the seams, causing the floor to curl, bubble, emit an odor and be easily displaced.

A high MVER can cause many of the same issues. Water will find a way out of a concrete slab. The correct adhesive should be capable of mitigating existing moisture emission to ensure flooring stays intact.

Even with all the testing, there’s still the question of new versus older concrete slabs. How does that affect the choices and processes? Well, it depends.

On a new slab, the RH will start out at 100 percent. This is referred to as “water of convenience,” and it will evaporate as the slab cures. It’s extra water that was in the concrete mixture itself. As the slab dries, the RH should go down.

However, there are issues that can lead to a higher RH in older slabs that have cured.

- Hydrostatic pressure - a slab below the water table(the area just below ground level where soil is permanently saturated with water) will experience constant water pressure and might either be lacking a vapor barrier or have an improperly installed vapor barrier

- Poor drainage - water around the building is not being properly diverted (generally on sloped surfaces)

- Busted pipes and leaks

This is why there are sometimes separate moisture maximums allowed for existing slabs when choosing an adhesive.

Here’s an example. An adhesive may be advertised as suitable for 99 percent RH, but if you have an older slab measuring 96 percent RH, the manufacturer could reject warranting the glue for your application.

This is because an old slab that has cured shouldn’t register an RH that high, unless there is a secondary source of moisture. The rejection doesn’t mean a lack of confidence in the glue; it means it’s necessary to find the cause of the moisture to make the best decision.

To ensure a successful, long-term installation, you’ll want to reach out to the facilities manager to find the source of the moisture.

How to Solve Moisture Issues in Concrete Floors

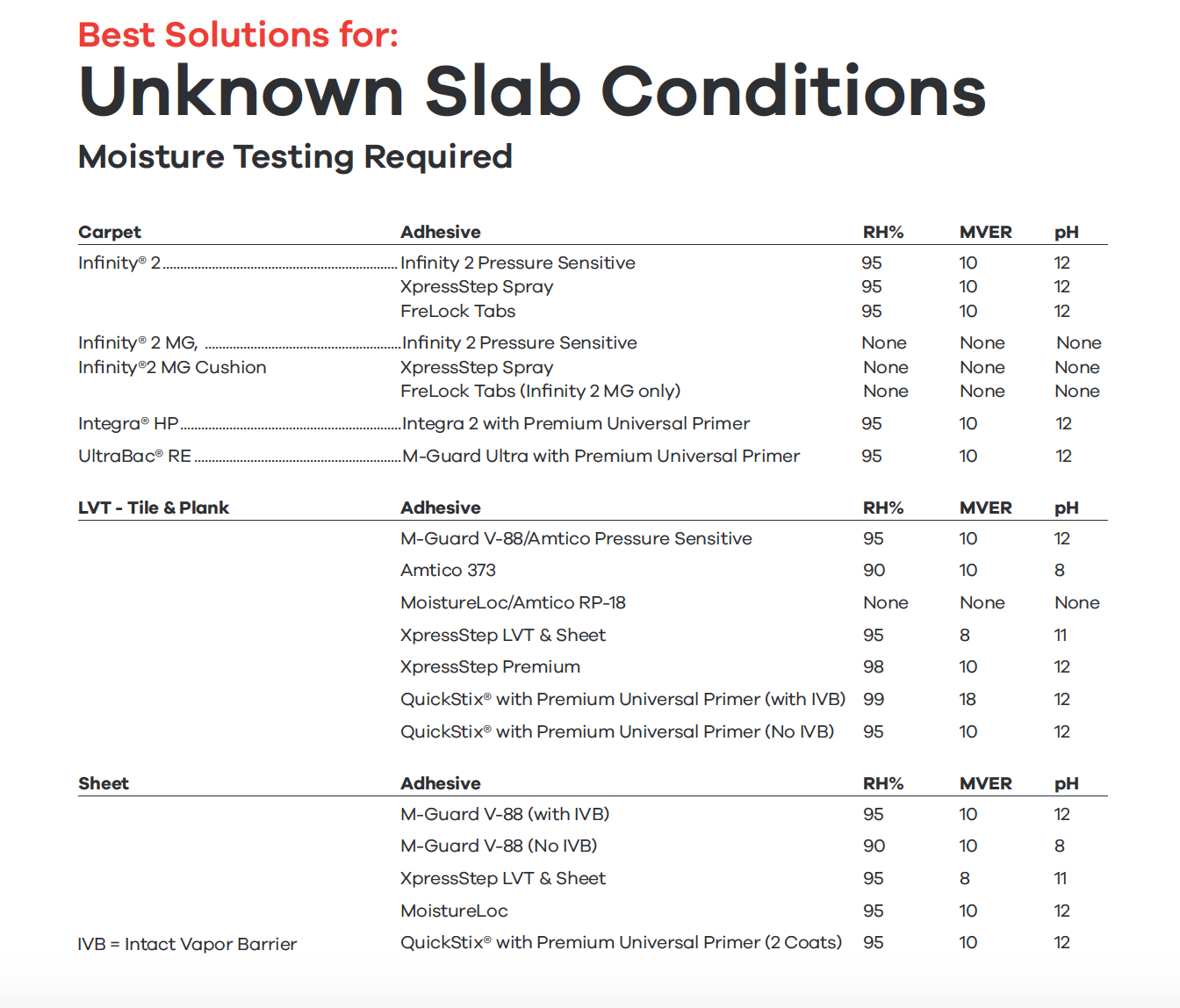

So you’ve done the testing and are now researching options to ensure you deal with moisture in the slab. What are the choices and considerations? Let’s look at the characteristics of several types of products.

Sealants

A chemical sealant can mitigate substantial moisture issues and seal the concrete while it cures which is a timesaver. However, all adhesive might not stick and many flooring manufacturers require a slab to be free of sealants for the warranty to be valid.

Moisture Suppressant Systems

This requires ensuring the adhesive and the flooring manufacturer are both compatible with the product. And, if you’re working with a new slab, waiting for it to cure can bring down high moisture readings.

Moisture Resistant Adhesives

When testing shows acceptable moisture readings for specifically engineered high moisture adhesives to be used, your best option is to use the adhesive along with a backing engineered for high moisture applications. This could be an impermeable moisture barrier that keeps water away from the flooring product or for carpet, a barrier that allows moisture to evaporate without negatively affecting the product. There are three primary options for moisture resistant adhesives:

- Spray Adhesives – quick to apply, usually high RH allowance and comes in an easy to use aerosol

- Trowel Adhesive – widely used but more time consuming, labor intensive and a bit messy

- Peel and Bond Adhesives – quick to apply, usually high RH allowance, low VOC and immediate traffic access to the floor.

Dry Installation

Another option in the presence of elevated moisture readings is to use either tabs or a floating/interlocking floor.

Tabs go up to no moisture testing required, and most floating/click installations are 90%+ RH.

· Tabs - no smell, no VOCs, ease of removal and immediate floor traffic

· Floating/Interlocking Floor (resilient floors) – click-together flooring has no VOCs, ease of removal and no downtime accessing the space

Tackle Your Underlying Moisture Issues Like a Professional

You understand the potential issues related to moisture and flooring installation. You know how to test. You know how a concrete slab should be prepped and what to consider for both new and existing slabs. And, you know some of the most common solutions to mitigate moisture issues.

No one wants to talk about moisture until it’s a problem.

Our hope is that this will help you avoid a moisture issue on the front end, but if you’re faced with a moisture problem down the road, no need to fear. You’re ready to tackle it like a pro.

Mannington Moisture Resistant Adhesives:

Would you like to learn more about moisture while earning AIA/IDCEC CEU credits?

Click below to request the CEU, Moisture: Why It’s a Hot Topic & How to Mitigate It in Flooring Installations