Modular carpet is a popular option for office space, it’s soft, absorbs sounds, and the design options with a modular carpet tile are endless. As a designer, you probably already know the benefits of using carpet so we want to help you choose the right carpet tile because not all modular carpet is created equally and the needs of your specific space will play a huge role in the type of commercial flooring you’ll choose.

How do you know which modular carpet is best?

In this article, we’ll look at some important considerations like size differences and the different ways to make an impact with installation and pops of color to help you decide which carpet works best for your office space.

At Mannington we’ve been manufacturing and perfecting flooring for 100 years, and we use one of the top fiber systems to ensure performance and long lasting durability.

Modular Carpet Construction: Design And Sizes

Modular carpet comes in myriad shapes and sizes, giving you the ultimate in flexibility for design.

You can choose from planks or squares, which affords options in different installation patterns and design options. Additionally, with modular tiles, you can choose to include pops of color with accent tiles in a sea of neutral or use different styles and colors to help with wayfinding in large areas.

At Mannington Commercial, we offer planks in 12” x 48” as well as 18” x 36”. We also offer square tiles in many of our collections that are 24” x 24”. With a wide variety of sizes, you have the best opportunity to create the perfect look in any area.

In addition to different sizes and colors, it’s important to pay attention to the type of construction in the tile. There are several different types of construction used in commercial carpets. Loop, patterned loop, cut and loop (with the cut portion called tip-sheared) and cut pile are the four main types of commercial carpet construction.

Loop carpets mean the loops tufted remain uncut in the tile, and the heights of those loops are even across the entire carpet. While these carpet tiles wear well compared to other construction styles, patterned loop carpet provides even better appearance retention. This is because patterned loop carpet is made of high and low loops in the carpet tile, creating a textured look. Patterned loop carpets are the best choice for high traffic areas because the construction lends itself to the best appearance retention.

Cut and loop carpet has both closed loops and cut loops, created by tip-shearing. A tip-sheared carpet is made by tufting higher and lower loops and then shearing the tops off the higher loops while leaving the lower loops intact, giving a textured appearance and pattern.

The downside of tip-shearing is that it has the potential to trap dirt more easily. Worse, tip-shearing is also more prone to getting crushed, making the pattern less-clear since those fibers are cut and exposed to the elements. Tiles with a tip-sheared design add a dynamic look to your space, but it’s best to keep them in small, private offices where there is not heavy traffic.

Transference, a Patterned Loop modular carpet.

Cut pile carpets are just that — all the loops are cut, exposing the ends of the fiber to matting and crushing. Limit the use of cut pile to low traffic areas. Choose dense, patterned loop carpets for corridors and heavily trafficked areas to minimize wear patterns. Additionally, choose medium colors that have patterns or multiple colors whenever possible to minimize the appearance of stains and soiling.

TARR (Texture Appearance Retention Rating)

TARR (Texture appearance retention rating) helps you understand the durability of the carpet you are specifying. The higher the TARR rating, the better your carpet will retain its appearance over time. The Carpet and Rug Institute (CRI) created this TARR Rating Fact Sheet that gives further details and helpful information when selecting carpet for specific areas.

TARR is meant to give you a better understanding of how well a specific carpet should perform in certain end-use applications based on the amount of foot traffic expected in that area by measuring the level of appearance change of a specific carpet after foot traffic.

The ratings are established through simulation wear tests and are based on a 12,000-cycle hexapod exposure conditioning test. How this simulation is performed is that the carpet sample is secured to a backing sheet that is mounted inside a rotatable drum with the pile surface of the carpet exposed. A metal hexapod, with six polyurethane studs, rolls randomly on the pile surface inside the rotating drum for 12,000 revolutions.

The resulting change in appearance is rated on a numbered scale from 1 to 5, with 5 representing no change in appearance, and 1 representing a severe change. The higher the TARR, the longer the carpet will retain its original appearance. For example, carpet with a 4.0 TARR will retain its original new texture appearance longer in various traffic conditions than carpet with a 3.0 rating.

There are three basic categories for TARR:

- Moderate, which needs a carpet with TARR greater than or equal to 2.5

- Heavy, which needs a carpet with TARR greater than or equal to 3.0

- Severe, which needs a carpet with TARR greater than or equal to 3.5

While there can be variables that affect the end use and level of foot traffic, it is important to use the right TARR rating for the right end use. Using carpet that does not meet the minimum guidelines for your space can result in significant wear and a shortened life cycle of your investment. Additionally, if you place a low TARR carpet in a heavy or severe traffic area, it is possible to void the manufacturer’s warranty. We would be remiss in not telling you that proper maintenance of your carpet can affect the lifespan of your carpet and its overall appearance throughout the lifecycle.

All Mannington Commercial carpets are madewith a minimum of 3.0 TARR (Texture Appearance Retention Rating), meaning any carpet you specify from us will be able to withstand heavy commercial traffic. This is especially important because it ensures quality. Additionally, the TARR on our carpets is tested and verified by an independent lab.

Density Of Carpet Fibers

In addition to TARR, keep in mind the density of the carpet. This is not the same thing as the weight of the face fiber. The weight of the face fiber of the carpet is measured in ounces. The density refers to the spacing of the fibers within the carpet backing. As you may have guessed, the higher the density the closer the fibers are together resulting in the carpet performing better in terms of retention and crush resistance.

Fiber

Perhaps one of the most important choices you can make when selecting modular carpet tiles is face fiber.

Most commercial carpet is made from nylon. As the Most durable of all synthetic fibers, nylon resists wear and abrasion and has good resilience, meaning that it bounces back well and isn’t as susceptible to indentation as other fibers.

Nylon also resists stains as well as mold and mildew. But there are different types of nylon fiber, and each has different strengths.

Fiber Consideration Basics

With any fiber system, you want to make sure to look at several features to determine the right fiber for your application. A few things to consider are:

● Type of nylon - nylon 6,6 vs nylon 6

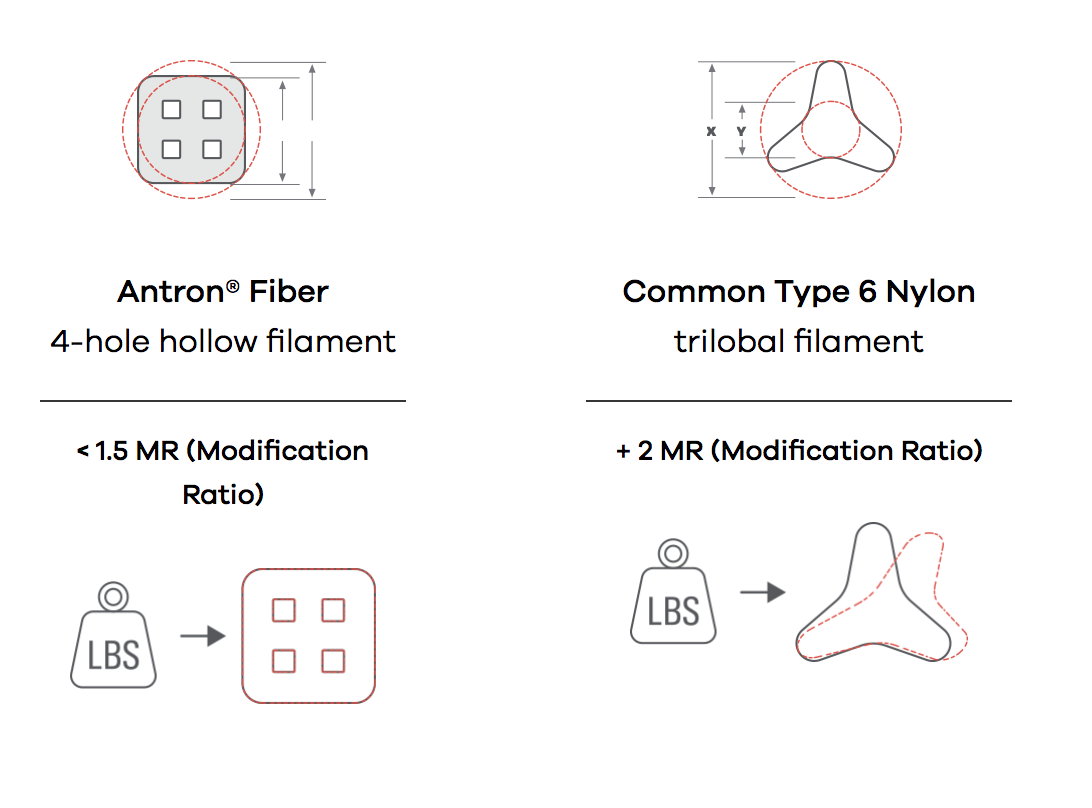

● Fiber shape - 4-hole filament vs trilobal

● Modification ratio

● Dye type - solution dyed vs yarn dyed

Nylon 6,6 vs Nylon 6

Nylon 6,6 and nylon 6 differ in their molecular structure, but both types have the benefits of nylon. Nylon 6,6 is made from two monomers, adipoyl chloride and hexamethylene diamine. Nylon 6 is made from one monomer, caprolactam. The reason ECONYL is made from nylon 6 is because they can break the nylon back down to the monomer chemically and regenerate it without losing quality. Nylon 6,6 is much harder to recycle. Antron uses Nylon 6,6 because their parent company invented it and it is deemed as superior by some.

Nylon 6,6 has long been considered a premium fiber because of its superior strength and durability. The tighter molecular structure of type 6,6 offers better defense against staining than type 6 because of its lower permeability. This means that type 6,6 slows down the diffusion of stains, allowing more time for clean up than type 6 nylon.

As the first nylon fiber made for carpet, DuPont established the dominance of nylon 6,6 in the industry early on and Nylon 6,6 has been able to maintain its superior position with regard to performance.

However, advances have been made in nylon 6 to shorten the gap between the two types.

Fiber Shape: 4-Hole Hollow Filament

Antron® Fibers are nylon 6,6, but even more important than being nylon 6,6 is how Antron fiber is constructed.

Only Antron fibers are constructed using a 4-hole filament structure which is the secret sauce for Antron’s ability to claim superiority in many categories of performance. Antron fiber has a sturdy, 4-hole hollow filament shape that makes it more resistant to crushing and matting than the trilobal design.

When choosing this fiber system, you will see the superior performance reflected in a higher price tag per yard. However, Antron has created a tool that helps you calculate the total cost of ownership so you can weigh your options carefully.

Unlike a typical type 6 nylon fiber, the unique shape and low modification of Antron fiber makes it difficult for dirt to settle. This ensures better release during vacuuming and hot water extraction.

Between cleanings, the 4-hole hollow filament structure also diffuses light, reducing the appearance of soil and helping the carpet look cleaner. Additionally, Antron fibers are cationic, meaning they are inherently stain resistant for most acid-based stains.

This is because fibers made via cationic polymerization will not accept acid-based dyes. Stains are in effect dyes, and most household-based stains are acid based; therefore, cationic fibers are much more resistant to stains than anionic fibers.

Fiber Shape: Trilobal

If you are struggling to find the budget to use the 4-hole filament Antron fibers, you can still have great performance from a trilobal construction. At Mannington Commercial, we’ve identified a top-performing nylon 6 fiber system in ECONYL® 100% Regenerated Nylon.

Unlike Antron, ECONYL uses a alto cross section trilobal design. While this does not provide the same superior level of crush resistance as the 4-hole filament, ECONYL performs extremely well in the resilience category, outperforming other fiber systems and placing second only to Antron fiber in tests performed by Antron on texture retention appearance.

It’s modification ratio is lower than typical nylon 6 and most mill extruded nylon, coming in at 1.8, which is why it performs well in crush resistance.

The trilobal design of ECONYL is more apt to allow dirt to settle than the 4-hole Antron fiber, but it’s cationic structure gives it a built-in stain resistance to most acid-based stains. Using a hot water extraction technique, ECONYL also performs second only to Antron in stain resistance in Antron tests.

Modification Ratio

Modification ratio is an important marker for how well the fiber holds its shape. The lower the number, the better it holds its shape. Antron’s 4-hole hollow filament fiber has a low modification ratio of less than 1.5, which contributes to its superior crush resistance. Contrast that to typical mill extruded nylon 6, which can have up to a 4.7 modification ratio.

ECONYL has a modification ratio of 1.8, which is lower than typical nylon 6 and many nylon 6,6 systems. At Mannington Commercial, we use fiber systems with the lowest modification ratios available for the best performance in the industry.

For a more in-depth look at carpet fibers, check out our Antron vs ECONYL article.

Dye Type: Solution vs yarn

Solution dyed yarns have the pigment “baked” into the fiber. This makes the yarn color fade-resistant, and typically the yarn will be bleach resistant with use of up to a 10% concentrated solution.

Yarn dyed means that the yarn starts out as white and is either space dyed with a number of colors over the span of the yarn or with one color, allowing for a range of designs that cannot be achieved with solution dyed yarns. Topicals can be added to yarn dyed constructions to help with fade and bleach resistance that is inherent in solution dyed yarns.

CoDi, a Solution-Dyed modular carpet.

Carpet Backing Types

While there are a number of backings offered in the industry for modular carpet, there are two basic types - hard-backed carpet tiles and cushion-backed carpet tiles.

Hard-back carpet tiles, like Infinity® 2 Modular backing, often offer a moisture barrier and are usually suitable for most applications with known slab moisture conditions with a low RH. Soft-back carpet tiles, like Infinity® 2 MG Cushion, offer a breathable surface that gives more cushion underfoot, better sound absorption and applications for a higher RH.

The Bottom Line

Modular carpet tile is an excellent choice for office space, and carpet manufacturers are making products with many different performance attributes and options. Now that you know what to look for, you can choose the best modular carpet for your needs.

You can choose from planks or squares, giving you options in installation patterns and design. You know about Texture Appearance Retention Ratings and not to put carpet with tip-shearing in an area with a lot of foot traffic. You know the basics of fiber consideration and how superior performance warrants a higher price tag per yard and how to calculate that so you can weigh your options.

Explore our performance pages to learn more about our product offerings.