Maybe you’ve been tasked with a healthcare design project. Or maybe you’ve made a career change from residential design to commercial, and vinyl isn’t a product you’re familiar with. Or perhaps you’ve been in the industry for a while, but you’d like to be able to explain resilient flooring in a deeper way.

Whatever the reason, we’re taking a deep dive into resilient flooring in this article—what it is, where it’s commonly used, and what forms and formats it comes in.

Let’s jump into it.

1. What is Resilient Flooring?

2. Where is It Commonly Used?

3. What Types of Flooring Are Considered Resilient?

4. What Forms Does Resilient Flooring Come In?

1. What is Resilient Flooring?

Resilient flooring is just that...resilient. It can return to its original shape after being compressed. It has a cushiony texture as opposed to hard surface floor without much give. According to the Resilient Floor Covering Institute, Resilient flooring is “a non-textile floor that provides underfoot comfort and characteristically bounces back from repeated traffic or compression.” It is basically a category of flooring in between soft flooring like carpet and hard flooring like stone or wood. But, even though resilient floors are more comfortable, they can be built stand up to the most strenuous of commercial applications.

2. Where is It Commonly Used?

Resilient flooring is commonly used in commercial spaces. It’s a popular flooring choice, because it offers durability, cleanability and scratch resistance combined with cushion comfort underfoot and safety features. Not to mention, it offers many aesthetic options! Resilient flooring can come in a variety of colors and patterns. With new digital printing technology, the visual options are almost limitless.

It’s often used in healthcare centers, education and retail buildings, gyms and yoga studios, hotels, libraries, office buildings, and even some multi-family housing facilities. As you can see, the places where resilient flooring is used are generally high traffic areas where safety is a priority.

3. What Types of Flooring Are Considered Resilient?

There are several types of flooring that fit in the resilient category. To create the characteristic “bounce back” feel, resilient floors are typically made of a mixture of fillers, binders, resins and color pigments. Filler materials can include synthetic fibers, ground wood, limestone, or other minerals. The material that binds the mixtures together is either asphalt (asphaltum) or resin. Here are four of the most popular types of resilient flooring:

1. Vinyl

Vinyl products are the most popular form of resilient flooring. They come in two main types: solid and composition. LVT (luxury vinyl tile) is the fastest growing segment in the industry, and it is in the solid vinyl category. VCT (vinyl composition tile) is the most common example of a vinyl composition product. Vinyl options are popular, because they offer all the qualities of resilient flooring along with a unique variety of color and design options.

2. Rubber

Rubber can be either natural or synthetic. It originally comes from rubber trees, but recycled rubber is often used to make flooring. Rubber resilient floors can also be manufactured synthetically, and they function just as well. While it may be a slightly pricier option, clients like rubber because it offers durability, comfort under foot, ease of maintenance, and it’s naturally based.

3. Cork

Along with rubber, cork is a great option to get that natural aesthetic, and it’s popular with eco-minded clients. Cork originally comes from the bark of cork oak trees, so harvesting cork does not require cutting trees down. It is naturally mold and mildew resistant and offers exceptional cushion under foot.

4. Linoleum

Linoleum is the original resilient flooring. It’s been around even longer than vinyl. It’s typically made of a mixture of wood, limestone, cork, linseed oil and resin. Linoleum is an affordable option with many of the same benefits that more expensive types of resilient flooring have like durability and ease of maintenance.

Laminate flooring is sometimes confused as being a type of resilient flooring. It’s tricky to categorize, because of its multilayer construction. But ultimately, it’s too wood-based to be considered resilient. It doesn’t have that “bounce back” factor that is characteristic of resilient flooring.

4. What Forms Does Resilient Flooring Come In?

Whatever the type, resilient products come in three forms: sheet, tile, and plank.

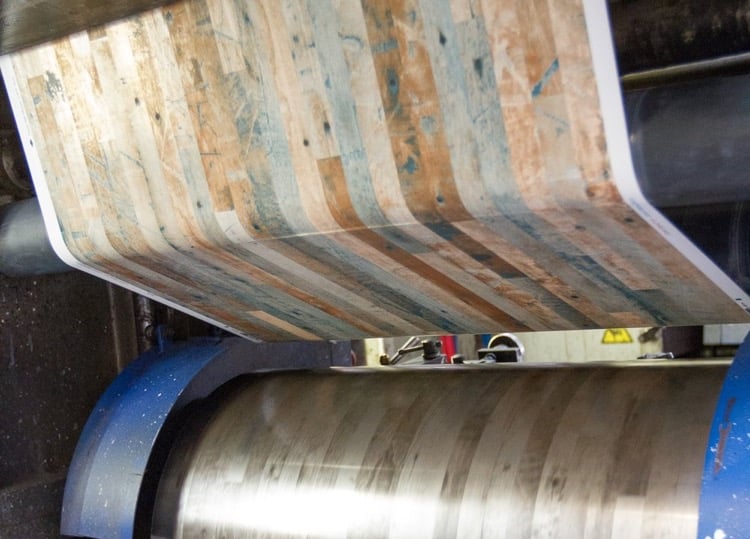

1. Sheet

Sheet flooring literally comes in large sheets of rolled up material. The width and length of sheets vary. Sheets are typically between six and twelve feet wide with varying lengths. Most often, in sheet format, the length exceeds the width. Mannington Commercial offers multiple widths and lengths, so we can accommodate different spaces.

The benefit of sheet flooring is fewer seams and a quicker installation, which translates to cost savings. If you’re lucky, you can cover your entire floor with just a few seams. Some rooms can be done using only one or two sheets of flooring. Sheet flooring tends to be more flexible and less dense than tile or plank products.

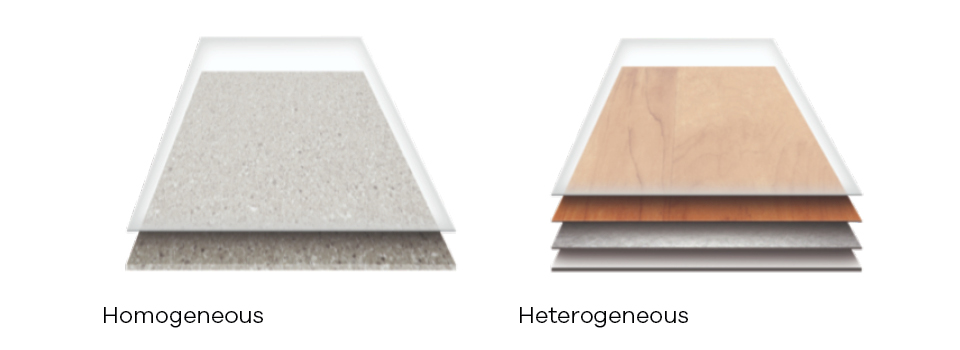

Mannington Commercial is one of only a few manufacturers that can produce sheet flooring both homogeneously and heterogeneously. These composition differences affect the wear, end use performance and the visual of the flooring.

- Homogenous means that the flooring is one substance—it is a single layer, top to bottom. If you chip this type of flooring it is less obvious than a heterogeneous flooring because it is the same throughout. The single layer can be quite thick and can offer vibrancy and depth of color.

The best way to tell a homogeneous product from a heterogeneous product is to flip the product over and look at the back versus the front. Essentially, if the product looks the same on both sides, it’s homogeneous. Examples of homogeneous sheet flooring include sheet vinyl, rubber, vinyl composition tile, solid vinyl tile, and cork—though you can also have cork floor tiles with a layered, heterogeneous construction.

- Heterogeneous sheet flooring has multiple layers, typically with separate chemistries for each layer. You can tell when a product is heterogeneous because it doesn’t look the same on the top and bottom. Think of a hamburger. When you look at a cross section view of the burger, you see different layers. A cross section view of heterogeneous flooring shows layers in a similar way.

Each layer serves a different function. There is typically a backing layer, which provides the bonding surface, several inner layers for form and stability, a printed layer, and a wear layer on top. From a design perspective, Heterogenous introduces printed layers which makes the variety of design options almost limitless. This feature brings a huge benefit to this category of flooring because of the range of style and design available. The visuals are protected by the wear layer. Examples include luxury vinyl tile, multilayered flooring, and heterogeneous sheet vinyl or printed sheet vinyl.

2. Tile & Plank

Resilient flooring can also come in the form of tile and plank. While these two forms are similar, their primary differences are in shape and aesthetic. Planks are typically rectangular and designed to resemble the look of wood, while tiles are often square and printed to look like stone or ceramic. However, both tile and plank can feature abstract or textile designs as well.

Tile and plank flooring is less flexible and denser than sheet products. Because it’s not as plasticized, it can’t be rolled up. So, it’s typically packaged lying flat in cartons instead of rolled in boxes like sheet flooring. Examples of tile and plank flooring include vinyl composition tile, solid vinyl tile, luxury vinyl tile, multilayered flooring, and rubber.

That sums up the commonly asked questions about resilient flooring. When it’s time to specify a resilient flooring product, you’ll be ready. With knowledge about what resilient flooring is, where it’s used, and the types and forms it comes in, you’ll have the knowledge you need to make an informed decision on your new floor!

If you’re interested in putting your new flooring knowledge to the test or learning more about this category of flooring, we have an accredited CEU on the topic. Contact your local sales rep if you’re interested.

Would you like to learn more about resilient flooring while earning AIA/IDCEC CEU credits? We have a CEU for you. 👇